Indentation: Advanced usage

Tip calibration

Initialize the datafile containing the calibration measurements, using nuMat=0.18 as the tip’s Poisson’s ratio:

from nanoindentation import Indentation, Tip

i = Indentation("FS_Calibration.xls", nuMat=0.18)

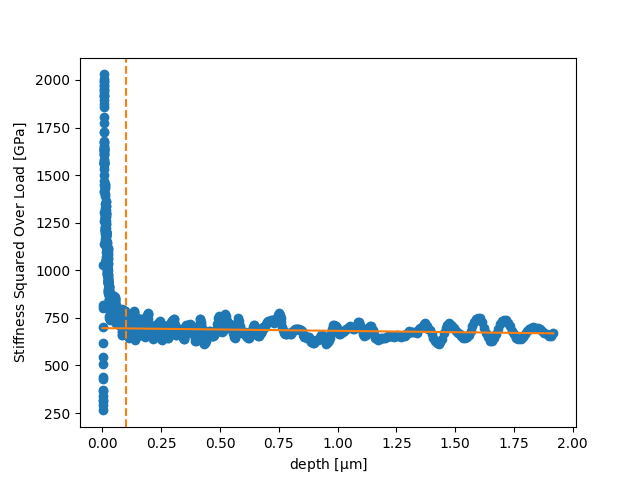

i.plotAsDepth("K2P")

i.plotAsDepth("K2P") plots \(stiffness^2/load\) as a function of the depth and the orange line should be horizontal.

Perform the calibration. Specify “True” for plotStiffness and plotTip to check the plotted compliance and shape of the tip:

i.calibration(plotStiffness=True, plotTip=True)

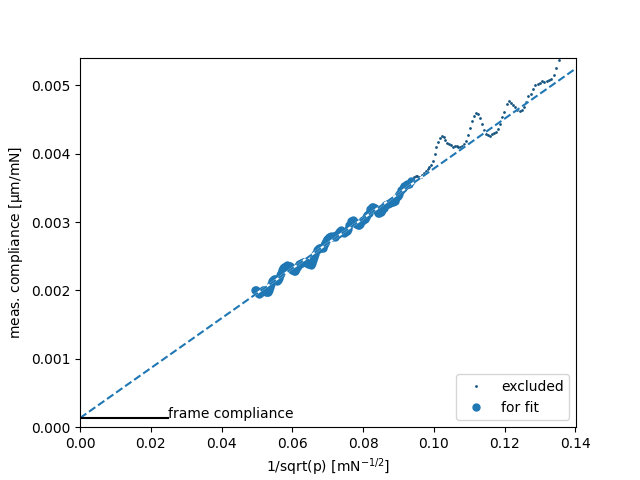

Stiffness

The datapoints at larger forces (smaller values on the diagram) are used for the fitting.

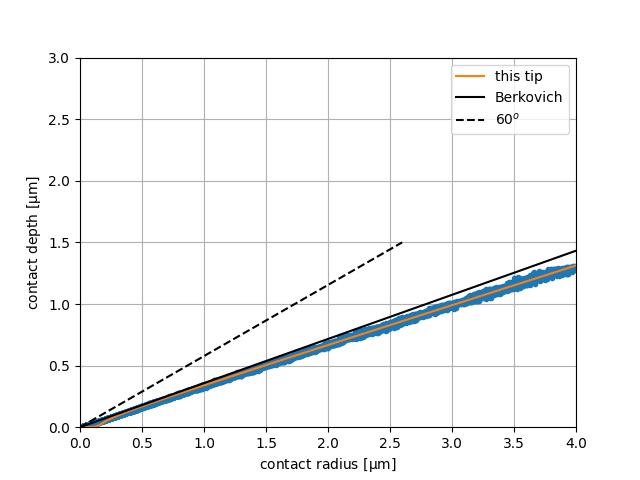

Tip Shape

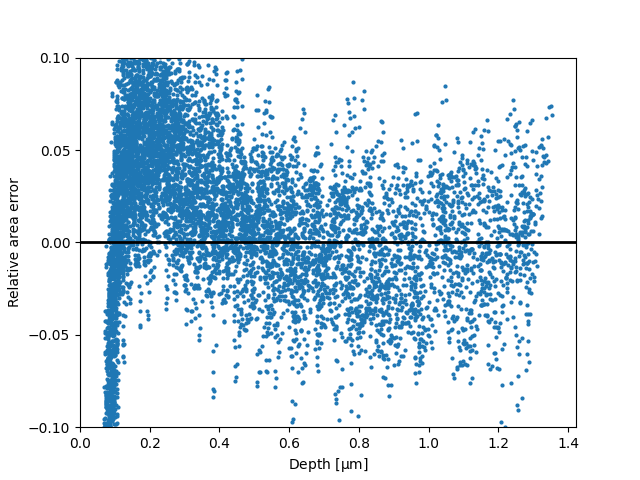

Error in tip shape calibration

The blue points represent the experimental data. The blunting of the used tip is easily noticable at the very beginning of the orange line. A relative error of 5-10% is typical.

(To zoom in the blunted part of the tip, use plotIndenterShape() at e.g. maxDepth 0.25):

i.tip.plotIndenterShape(maxDepth=0.25)

Finally, initialize the measurement data, specifying the tip as the just calibrated one:

j = Indentation("NiAl_250nm_TUIL_max_depth_1000nm_GM3_SM_previousGM1.xls", tip = i.tip)

Continue the analysis with the calibrated tip as described in the “Getting started” secion.

Surface detection

Inaccurate surface detection can be critical for achieving reliable indentation results, especially for compliant materials.

When loading the file, specify the surfaceFind = {} parameters for example:

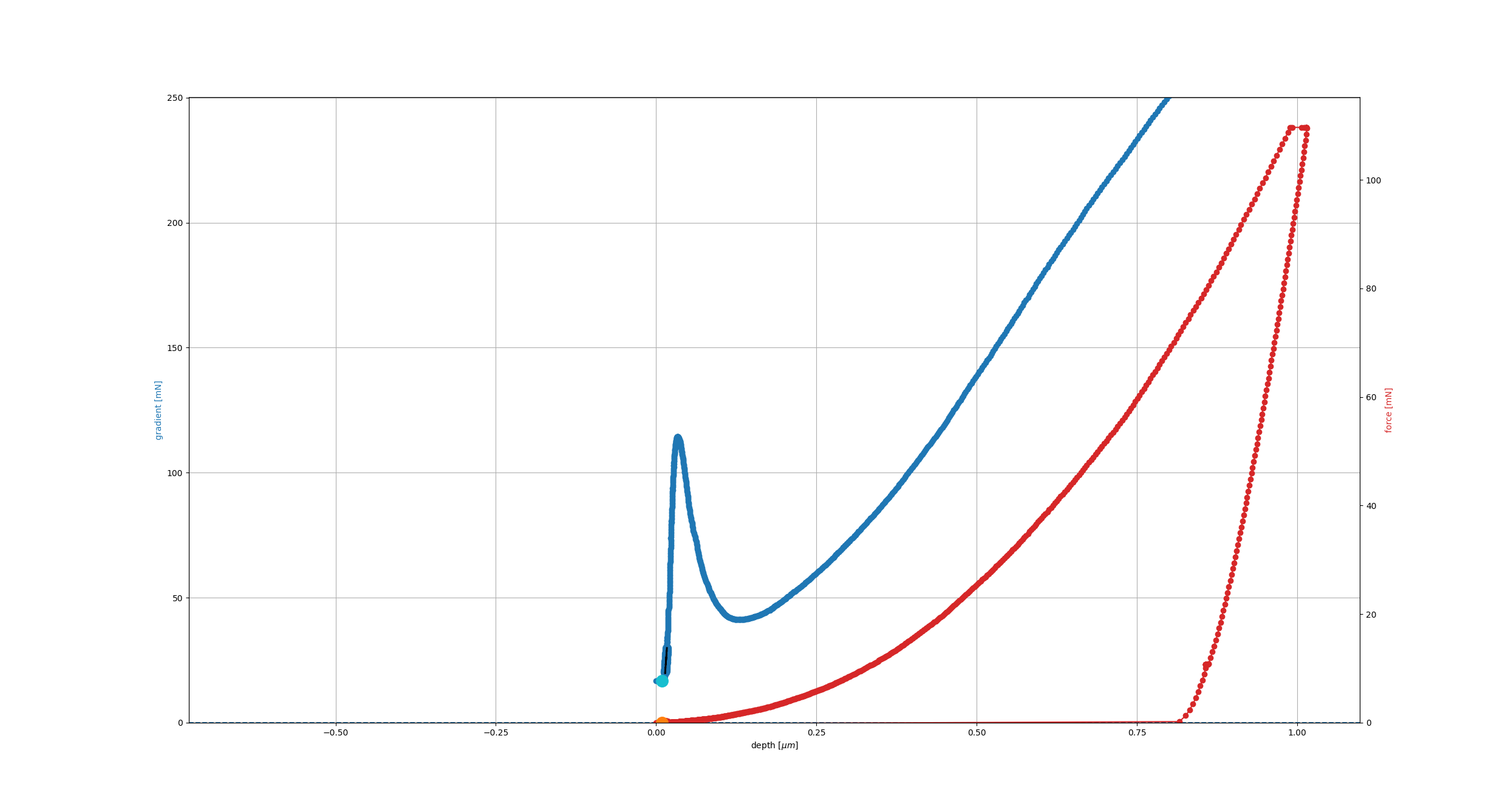

i = Indentation("Nafion_15_100_5.hdf5", nuMat = 0.5, surfaceFind={'gradient':0.1, 'filt':10, 'plot':True})

If a mistake in polyfit appears, increase the value for gradient. If the datapoints for the gradient (blue line on the graph) are very noisy, increase the filtering value.

Additionally, an interval for the gradient can be set. In this case the gradient interval would be used to extrapolate backwards to zero force and the resulting point would be used the surface.

Surface detection,’gradient’:[20,30]